HPC Hoses: Data center cooling solutions

Tudertechnica introduces a new range of high-performance technical hoses, specifically designed for liquid cooling systems in high-density environments. The exponential growth in demand for computing power, networking, and storage in data centers has made thermal management a critical challenge. Liquid cooling systems, leveraging the superior thermal capacity of water or other fluids compared to air, have become essential to ensure sustainable operations and reduce energy costs.

These solutions are engineered to optimize heat dissipation, ensure operational continuity, prevent overheating and damage to electronic components, and extend equipment lifetime. They also contribute to reducing energy costs and inefficiencies associated with traditional systems.

HPC Series: hoses designed

for thermal efficiency.

for thermal efficiency.

The HPC (High-Performance Computing) Series is developed to meet the needs of modern data center infrastructures. This portfolio combines engineering innovation, advanced customization, and precision industrial manufacturing, with every component designed to guarantee long-term performance and seamless integration under critical operating conditions.

All HPC hoses for data centers are designed to withstand high mechanical loads while maintaining optimal flexibility, ensuring consistent performance in high-density operating environments.

EPM (EPDM Rubber Category) Hoses: Resistance and Compatibility with Glycol-Based Fluids.

EPM (EPDM Rubber Category) Hoses: Resistance and Compatibility with Glycol-Based Fluids.

EPM (EPDM rubber category) is a heat-resistant polymer offering excellent compatibility with PG25 and other water-glycol coolant solutions. To preserve fluid purity and composition, the compound is peroxide-cured. The addition of fungicides and bactericides prevents microorganism growth, ensuring long-term safety and reliability.

TURAD® HPC (HB UL 94:2023 – UL RECOGNIZED HOSE)

Smooth white EPM (EPDM category rubber) compound, peroxide-cured, heat-resistant. Black smooth technopolymer cover with textile finish, flame-resistant and compliant with UL 94:2023 V-0 classification. Operating temperature: -40°C to +120°C (-40°F/+248°F). Resistant to abrasion, aging, ozone, and UV radiation. High flexibility. Fittings available.

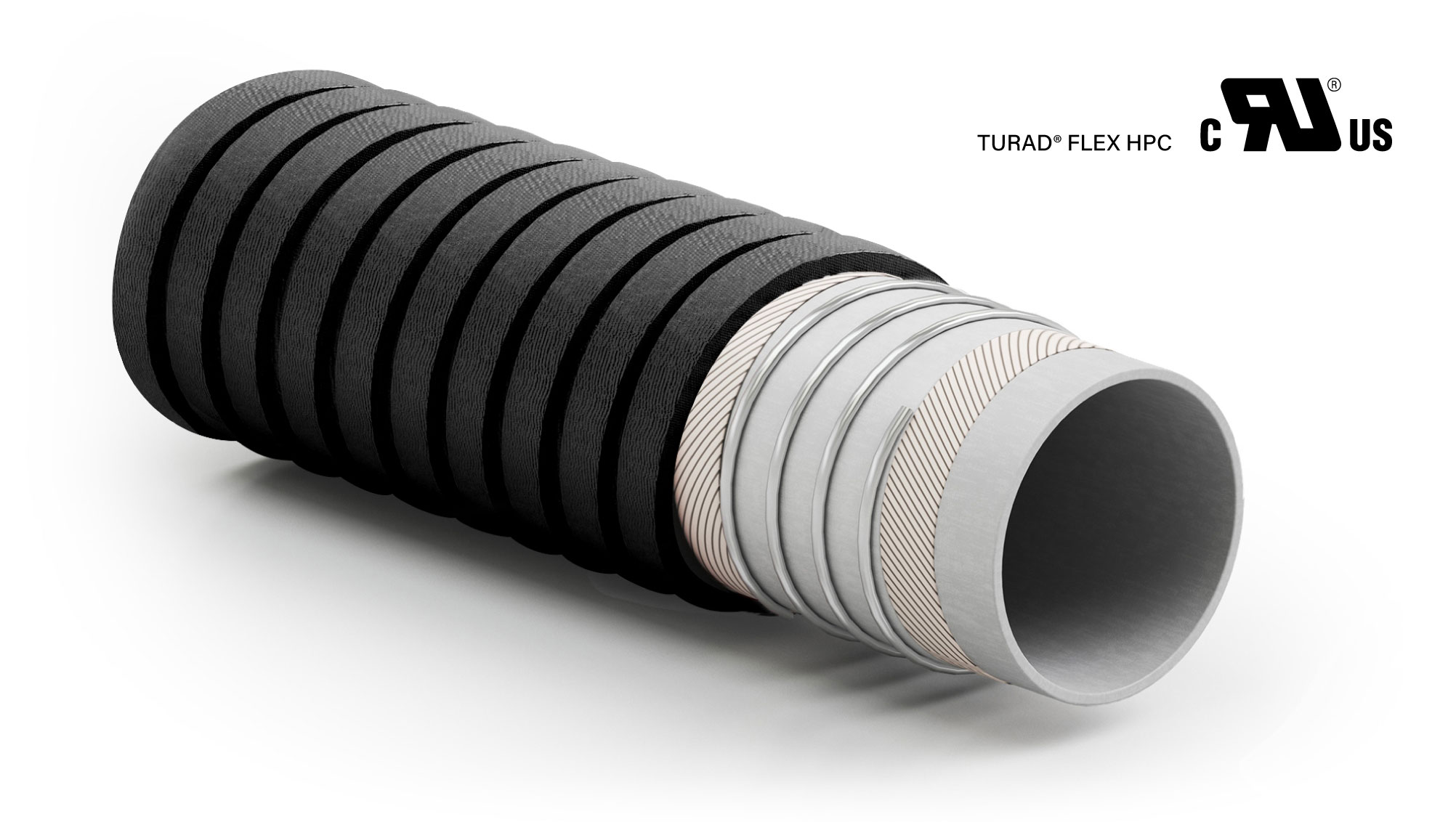

TURAD® FLEX HPC (HB UL 94:2023 – UL RECOGNIZED HOSE)

EPM (EPDM category rubber) corrugated version with extreme flexibility, ideal for complex installations, offers maximum adaptability in compact spaces. Black flame-resistant cover, UL 94:2023 V-0 classified. Operating temperature: -40°C to +120°C (-40°F/+248°F). Resistant to abrasion, aging, ozone, and UV radiation. High flexibility. Fittings available. Fittings available.

TURAD® FORM HPC (HB UL 94:2023 – UL RECOGNIZED HOSE)

Smooth white EPM (EPDM rubber category) compound, peroxide-cured, heat-resistant. Heavily corrugated black synthetic polymer cover, enhancing flexibility, flame-resistant with textile finish. UL 94:2023 V-0 compliant. Operating temperature: -40°C to +120°C (-40°F/+248°F). Resistant to abrasion, aging, ozone, and UV radiation. High flexibility. Fittings available.

TURAD® HPC EVOLUTION

Suction and delivery hose designed for heat exchange solutions in data center cooling. Optimal compatibility with PG25 and other deionized water/glycol mixtures, preventing fluid contamination. Extended temperature range: -40°C to +170°C (-40°F/+338°F), with peaks up to 180°C (+356°F). Reinforced with synthetic fabrics and galvanized steel wire spirals. Black synthetic polymer cover, resistant to abrasion, aging, ozone, and UV. High flexibility. Fittings available. Also available in FORM version.

PTFE Hoses: Chemical Inertness and Extreme Flexibility.

PTFE is a heat-resistant polymer with a very low friction coefficient (0.02), ensuring excellent fluid circulation. It offers outstanding chemical compatibility with PG25 and other water-glycol solutions and is also suitable for immersion cooling systems using dielectric fluids. Being chemically inert, PTFE prevents absorption and release of substances, maintaining fluid purity and composition.

TUFLUOR® PTFE HPC (HB UL 94:2023 – UL RECOGNIZED HOSE)

Suction and delivery hose for heat exchange solutions in the most demanding data center cooling applications. With its low friction coefficient ensures efficient fluid circulation. Offers optimal compatibility with PG25 and other deionized water/glycol mixtures. Co-extruded TEFLON™ PTFE (transparent/white pigmented), resistant to high temperatures, mechanical stress, and oxidation. Black smooth technopolymer cover with textile finish, flame-resistant, UL 94:2023 V-0 compliant. Operating temperature: -40°C to +150°C (-40°F/+302°F). High flexibility. Fittings available.

Silicone Hoses: wide temperature range and insulating properties

Silicone offers excellent heat resistance across a wide temperature range (-60°C to +200°C / -76°F to +392°F), while maintaining flexibility. It provides excellent insulating properties, resistance to ozone and UV, and low flammability. Its low thermal conductivity ensures outstanding insulation performance. Compatible with PG25 and other glycol-water solutions. The gray silicone cover compound and hose construction are classified V-0 according to UL 94:2023.

TUSIL® RAD HPC (V-0 UL 94:2023 – UL RECOGNIZED HOSE)

Suction and delivery hose suitable for heat exchange fluids. Excellent compatibility with PG25 and other water-glycol coolant solutions. Translucent silicone, heat resistant. Reinforced with high-temperature resistant yarns and stainless-steel wire spiral. Glossy gray silicone cover, resistant to abrasion, aging, ozone, and heat. Flame-retardant, self-extinguishing, with low smoke toxicity, and low smoke opacity. Operating temperature: -60°C to +200°C (-76°F/+392°F). Fittings available.

Performance & Benefits: reliability, efficiency, and operational safety.

The HPC hose range is developed to ensure reliability and operational continuity in liquid cooling systems for data centers. All hoses are designed to minimize the risk of failures and leaks, extending equipment life. Manufactured from selected materials, they guarantee thermal stability and resistance to intensive loads, reducing downtime.

Our hoses are designed for use with various fittings, providing maximum flexibility of integration into different systems.